One of the big jobs I wanted to get completed before the start of the season was to actually downgrade something on Nautilus!! We had a Naviops computer system on the boat for controlling all of the electrical systems (lights, pumps, navigation systems).

In principle this is a great idea, but in practice, when applied to a “live aboard” situation it’s not great. The main issues we had with it were:

- it wasn’t completely reliable. (it’s code). after periods of time it could lock-up, circuits would randomly turn off or we’d struggle to turn something back on again… As an example, we had 3 instances of the waste water pump turning itself off whilst the washing machine was running. The water backed up through the system and flooded the shower and into the bilge.

- power consumption – there was no getting away from the fact that you needed to have 2 computers running at all times plus the switching units around the boat. When we’re continually counting “watts”, I wanted something more efficent. A simple on / off switch doesn’t consume any power.

After a year on Nautilus, we decided the time was right to switch it out for something else.

Back to basics

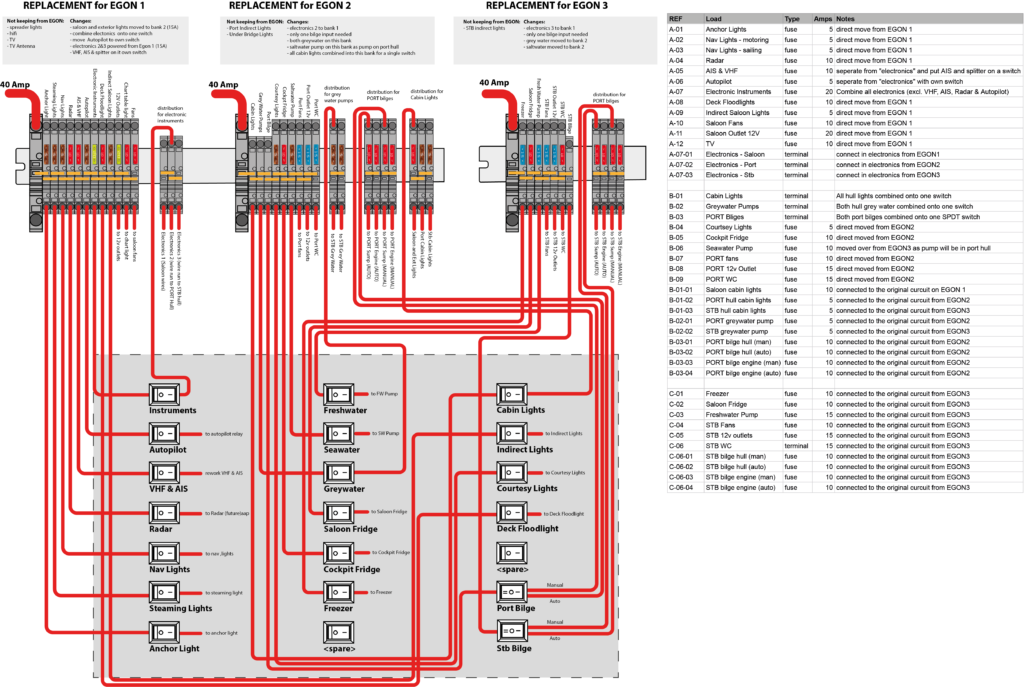

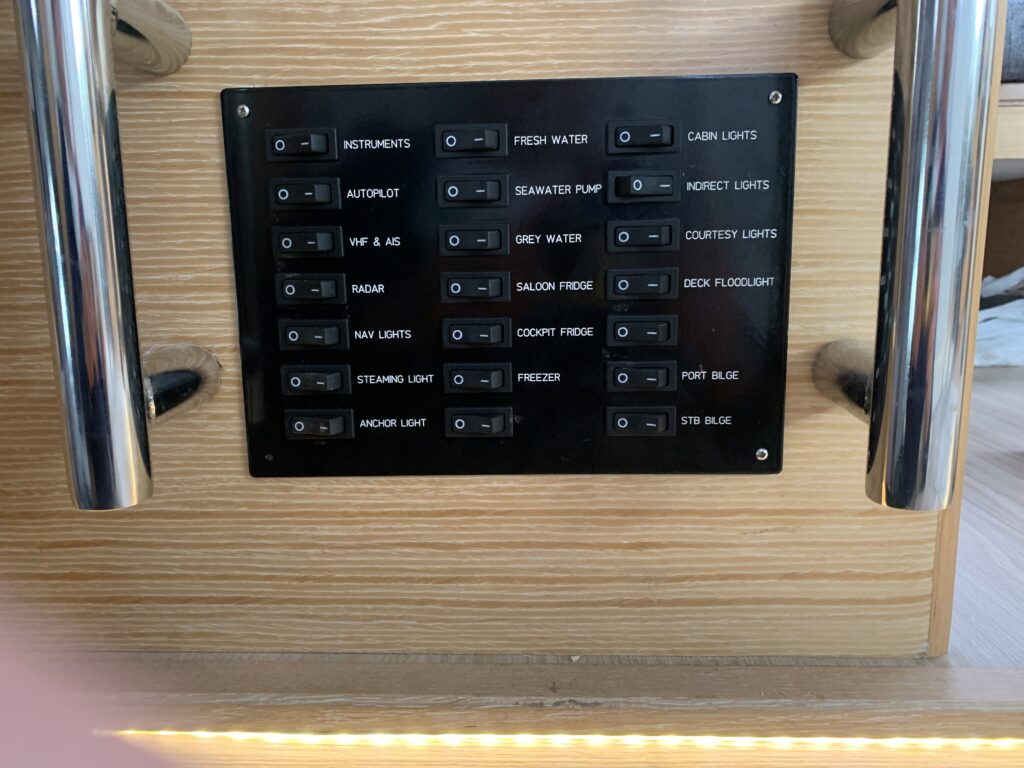

I evaluated various options and whether to try to keep some of the naviops components. However, back to the principle of “keep it simple stupid”, I decided a regular switch panel was the way to go. The first step was to do an audit of the boats systems and get the first design pulled together.

I was then able to order all the components, including a custom switch panel from Germany, (which wasn’t’ nearly as much as you might expect).

The goal was to try and keep things simple, but with a bit of granularity too:

- I wanted to be able to switch on instruments without the autopoilot, so if we’re at anchor I can keep an eye on the wind and depth, but without drawing extra power.

- I wanted to be able to manually control the fridges and freezer

- I wanted some sapre switches too for future upgrades

- Based on prior experience we needed to clearly see which pumps were on or off.

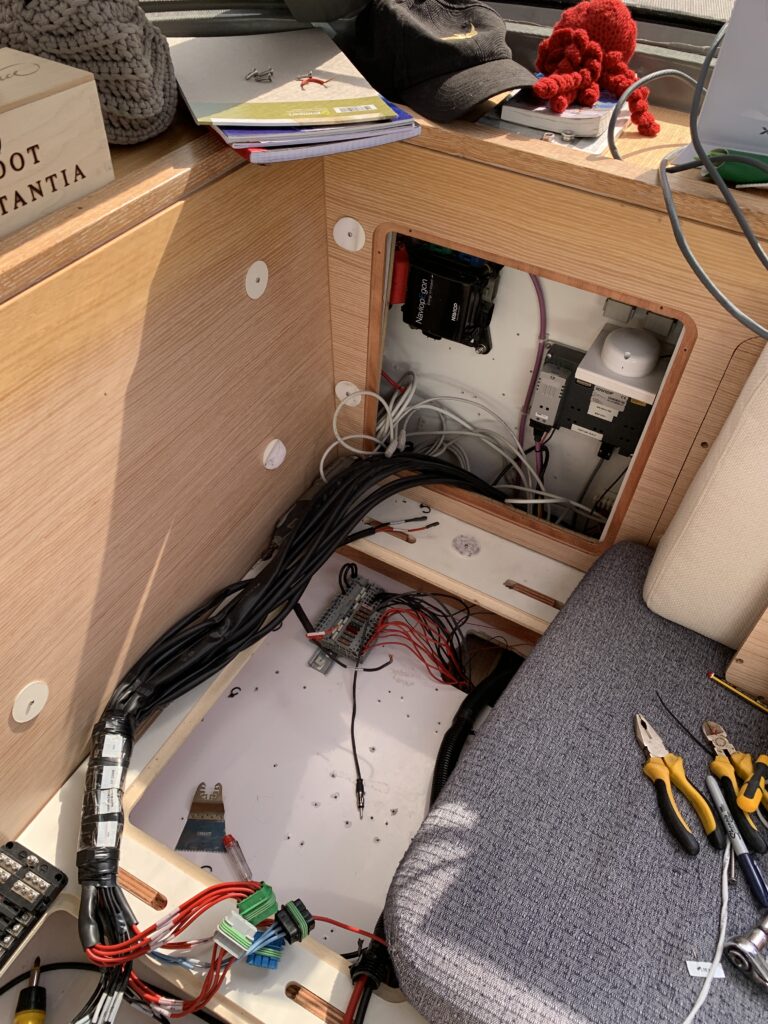

The Install

Over the course of 3 days I pulled the boat apart and put it back together again. Lots of cups of tea, sore hands, a few cuts and a very patient Tatum and it’s all done!

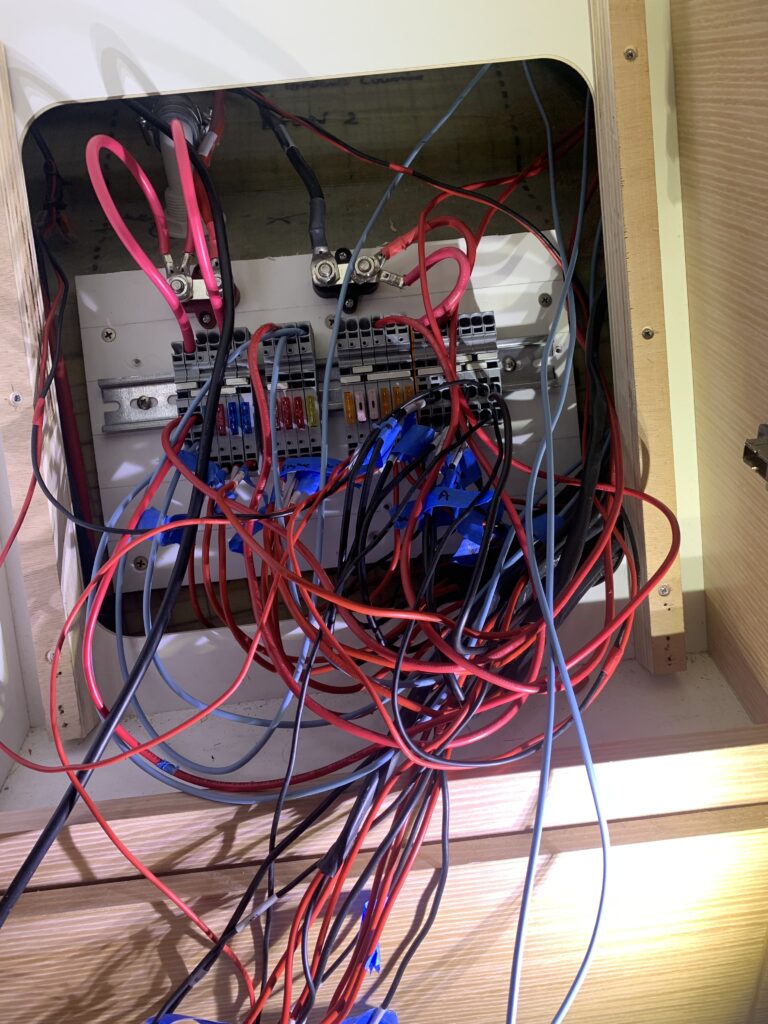

Out with the old:

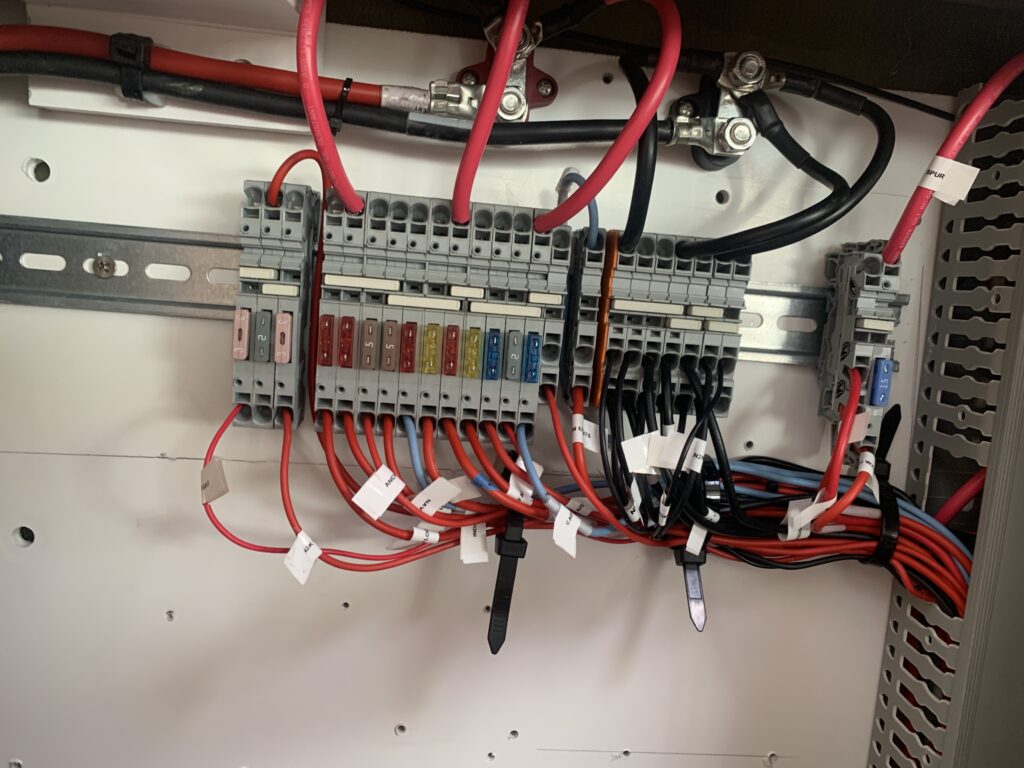

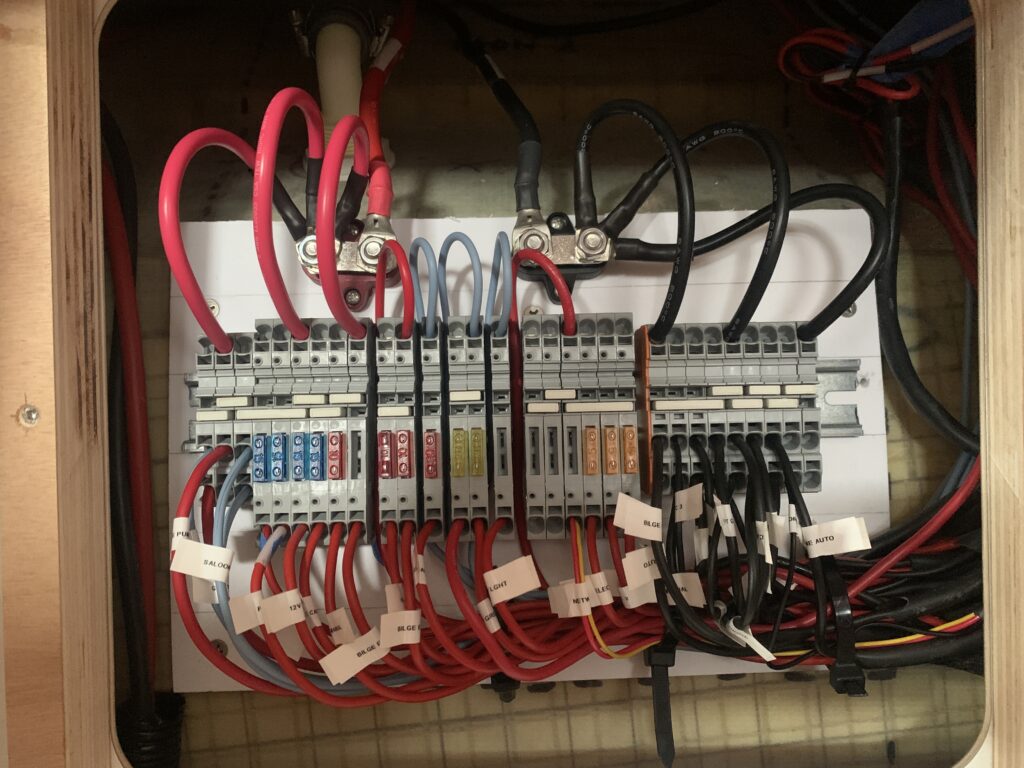

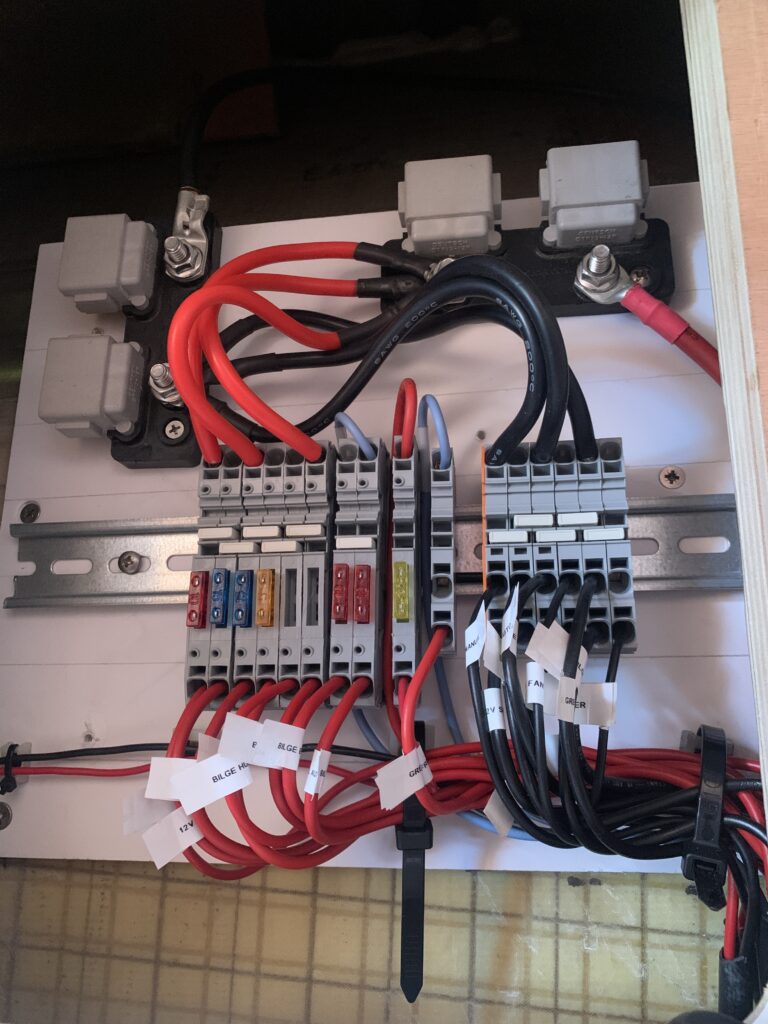

And in with the new:

I’m really happy withe the result. I was able to go through circuit-by-circuit to properly label everything up and remove redundant wiring from the boat. The is a real satisfaction to building your own modular fuse panel for just what you need.

My original plan had been to try and put all the fuses in one place, but in the end it made more sense to keep the 3 different zones on the boat and just run wires back to the switch panel.

Lessons learned

I did need to adapt the design as I went (and will go back to update the original schematic I drew). Here are the top few things for anybody who is interested:

– The way the wiring is setup on the boat makes it very difficult to have all the fuses in one place. Instead I opted to keep the same 3 locations that Navops had and have the panels there. I was then easier to run cables back to a switch panel.

– The WAGO system is great for building a fuseboard, it meant I could easily move things around as I decided where to put the circuits, You can just add / remove things as necessary. However, I did need to work out how to go from the 25mm2 trunk cable to the max 10mm2 cable that fits into the fuses. In the pictures you’ll see a terminal block with 3 spider legs. That allowed me to step down from one big cable to 3 smaller cables without loosing the overall area of the copper.

– As you might expect, some of the trunking got a bit tight and i’d still like to get the wiring even neater under the fuseboards

– Combining the two grey water tanks onto a single switch was a bit of a pain, in hindsight I should have kept them separate

– On the bilges i’ve gone for a slightly different design. The switch panel will turn on the AUTO pump, so they only run if there is water touching the sensor on the pump. Rather than having the manual override on the switch panel, i’ve put it in the compartment next to the pumps. I’m confident this is safe as they have their own dedicated fused circuits and I think it should work better as you’d want to see the pump before starting a manual override. Hopefully we’ll never need it!

Next steps are to update the schematic so it’s in Nautilus’s documentation. I’ve also decided i’m going to re-do the data network too. Whilst looking at all the 12V wires, I could see that the data wires needed some love too!

One Response

Hey good to hear you’re back on board and preparing for the season ahead. But what crazy amount of work for the electrical system. You’ll be ready for your HND now.